- Home

- >

- News

- >

- Trade News

- >

- Buy Supply 20mm 25mm Four Way Loopin Tee Box Company Factory

Buy Supply 20mm 25mm Four Way Loopin Tee Box Company Factory

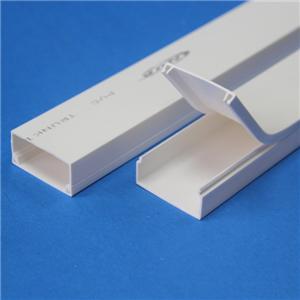

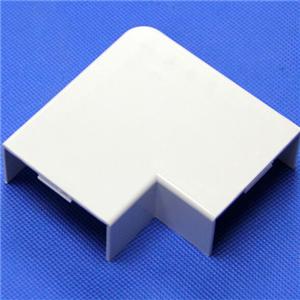

20mm 25mm Four Way Loopin Tee Box

Buy 20mm 25mm Four Way Box Factory

Today, the demand for highly specified aggregates means that smaller top-level products are better than in the past. This means that fragmentation applications must be equally accurate. How to crush materials in the first time without adjusting size or stockpiling oversize products?

Efficiency can be defined by the ratio of the work done by the machine to the energy provided. To apply this sentence to your crusher, in your reduction process, you are producing the size of your market demand.

In the past, quarries produced aggregate products of single size up to 40 mm. However, the trend of high-specification aggregates means that products become more and more sophisticated. At present, many quarries produce coarse aggregates of no more than 20 mm; for coarse aggregates of more than 10 mm, it is normal to store them for further fragmentation.

Here are some tips and best practices to keep your website smashing efficient and reduce the amount of fines.

Jaw crusher

Jaw crusher is a compression crusher. The material is reduced by squeezing the feed material between the moving steel sheet and the stationary steel sheet. The size of discharge is controlled by setting or space between the two pieces of steel. The tighter the settings, the smaller the output size and the lower the throughput. Jaw crushers are mainly used for primary crushing; they are seldom used as secondary crushers.

As compression crushers, jaws usually produce the roughest materials because they break the natural weakness lines of rocks. Jaw crusher can be used as an excellent primary crusher to prepare for subsequent rock processing stages, such as washing, grading or secondary crusher.

General Efficiency Skills

Grease lubrication system is superior to oil lubrication system.

Annual radial clearance inspection of main engine bearings should be recorded to track bearing wear.

Minimum flow settings should not exceed full-load amperes.

Don't crush the barrel with too much material on the chin. This area is not considered to be part of the crushing chamber.

Supply 20mm 25mm Looping Box

When lubricating oil is used, it is recommended that the bearing be sampled regularly.

The unloading width of the hopper of the unloading conveyor and crusher should be greater than that of the crusher.

Sufficient tension must be applied on the elbow plate to ensure proper alignment.

Efficiency Tips

Try to air any compression crusher. Remember, we use gravity and the weight of the material to push or force the material through the cavity. Because the material will break in the compressor to fill the cavities or voids in the chamber, the non-throttling chamber will produce a more plate-like output than the throttling chamber.

Feeding efficiency

Jaw crusher usually adopts throttling mode, which can maximize production capacity and ensure uniform particle crushing. This promotes one-to-one rock crushing, which breaks flaky or flaky particles. If you're looking for fewer fines, dripping materials into jaw crushers can do this; however, this will have an adverse impact on particle shape and reduce throughput and hamper crusher efficiency.

Ideally, the feed rate should not be switched from a throttle to a non-throttle, as this will cause problems downstream of the secondary processing plant. In practice, many jaw crushers adopt this intermittent mode because of the clearance between feeds transported from quarries. The feed of jaw crusher should be pre-screened with ash screen before crushing to remove finer material than the closed side setting (CSS).

20mm 25mm Tee Box Company

Suggestions on efficiency

In practice, many jaw crushers fail to meet the design capacity; this is because subsequent processing plants do not have enough capacity to deal with the amount of material produced when the jaw crusher works to the maximum capacity.

Fragmentation settings: efficiency

Ideally, the reduction ratio of jaw crusher should be 6:1. There are different ways to calculate the reduction ratio, but the best way is the so-called P80 factor. Then, the reduction ratio is calculated by comparing the input feed size of 80% and the traffic size of 80%. The finer the CSS, the larger the proportion of fine powder produced. The CSS of jaw crusher helps to determine the angle in the chamber, usually 19 to 23 degrees. Excessive angle can cause the breaking chamber to boil; this is where the jaw plate can't grasp the rock, and the rock keeps sliding up and down to avoid crushing. When the machine is set tighter, the angle will become flatter.

The jaw crusher is designed to produce ideal material for secondary crushing. The best particle shape usually occurs in materials of the same size as CSS. Smaller sizes will contain a higher proportion of elongated particles because they pass through the crusher without being touched.